To fully understand your requirements and challenges in developing new color and additive masterbatches, Penn Color has invested in a wide range of application testing equipment to screen and validate performance attributes in a simulated production environment. Through our focus on customer service, we have formed strong relationships worldwide in nearly all industries, including plastics injection molding, extrusion, blow molding, compounding and polymers development and more. Our broad industrial experience has uniquely positioned our applications laboratory to provide quick and targeted solutions that are on point for your industry.

Our Plastics Application Formulators will work closely with you to:

Penn Color uses an internal method to screen pigments/dyes, additives and carrier used in master batches formulated for applications using oxygen scavenger. This ensures your package is formulated with the optimum ingredients compatible with your process and final application.

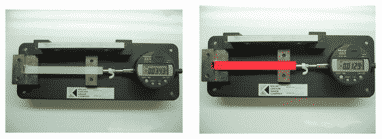

The instrument can measure the kinetic and static coefficient of friction on films to determine how they will perform in you process and end use application. This is useful in measuring a films ability to block or resist sticking upon roll up and take off. Penn Color offers a range of Antiblocking additives that can be tested in your polymer and film thickness to gauge performance.

Pigments and additives can greatly influence the critical dimensions of closures, lids and molded parts. Penn Color internal test method for dimensional stability can screen raw material to arrive at the best selection for your application.

Penn Color is equipped with two fiber spinning pilot lines capable of producing Nylon, PET or Polypropylene fiber for color matching, quality control and research & development exhibits.

Each line is capable of producing fiber up to 1400 denier, with filament sizes as low as 18 denier per filament (dpf). The appearance of spun fiber is greatly influenced by color, gloss and texture. The gloss component is a function of the fiber’s cross section or morphology. As such, we offer a variety of fiber cross sectional shapes including round, tri-lobal and delta morphologies to best match the end use application.

The lines are also equipped with in line drawing and texturizing to simulate the aesthetics of residential and commercial carpet. Various displays are available including card windings and Pom Poms of cut yarn for tufted applications.

We offer full computer color matching services for quick and precise custom matches for your application. Penn Color operates two server based color matching and quality control systems which are fully integrated into Penn Color’s global network.

In addition to standard color matching services, our Fiber Group offers functional additives for woven and non-woven systems including UV stabilizers, Antioxidant and thermal stabilizers, molecular weight and IV boosters, melt strength additives, and stain resistant technologies catered to your end use application.

Instrumentation and Testing for Packaging: